In Which Phase of the Dmaic Process Is Fmea Used

Improve Phase DMAIC Improve phase is the fourth phase of DMAIC. So weve finally reached the final post in this six sigma mini series.

Dmaic Method In Six Sigma 5 Phases Complete Overview

Analyze Phase DMAIC Analyze phase is the third phase of DMAIC.

. Now we turn towards fixing them. FMEA is used in the Define and Analyze phases of DMAIC. From the analyze phase we receive the root causes of problems.

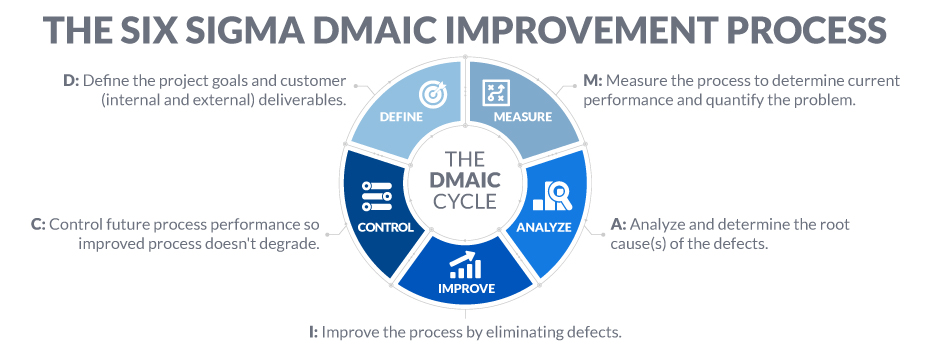

DMAIC is the problem-solving approach that drives Lean Six Sigma. Lean accelerates Six Sigma delivering greater results than what would typically be achieved by Lean or Six Sigma individually. However in Control an FMEA is updated based on real data and is helpful for continuous and ongoing improvement.

Once they have all been listed list the pros and. Root cause analysis RCA to uncover causes. No idea what that meansthe FMEA is historically useful in MEASURE when combined with the process map inputs SIPOC to determine the elements to be used in your data collection plan.

To build your understanding of the method and help you apply. Define Measure Analyze Improve and Control. Indeed it may be used to implement a new process or improve an existing process.

FMEA Failure Modes Effects Analysis was developed long before the DMAIC Methodology was launched and is a powerful tool for preventing both design and process failures. But this is one of the most challenging phases of the DMAIC process. This tool is great for creating possible solutions for problems that disrupt the efficiency of your current process.

Understanding the DMAIC process Fundamentally the DMAIC approach exists to bring structure to process improvement and problem-solving. Improve The Improve stage of DMAIC focuses on improving process performance by. The 2nd phase of a DMAIC Project.

Lean and Six Sigma complement each other. This phase focuses on measurement system validation and gathering root causes. In the Measure Analyze and Improve phases an FMEA is typically the result of brainstorming because quantitative data is usually not available.

Share this link with a friend. FMEA can be interrelated in different phases during any DMAIC Project. Question 7 of 20 50 50 Points In which phase of the DMAIC process might FMEA be used.

Question 14 5 5 points In which phase of the DMAIC process might FMEA be used. There are two distinct types of FMEAs. Having looked at the improve phase last time its now time to consider the control phase.

During Measure Phase FMEA can be used to identify what can go wrong with the process and can do prioritization to focus of a DMAIC Project and helps the team in. In the control phase of a DMAIC project the team focuses on sustaining the gains made in the improve phase. In other words during this phase teams focus on eliminating the root causes and implement the improvements.

The Improve phase focuses on you guessed it improvement. The main activity in the Analyze phase is to identify the potential root cause of the problem and arrive at the actual root cause. During the define phase it is used to identify processes that require improvements and are susceptible to failure.

The ___ phase of DMAIC addresses project management issues that answers questions about what will need to be done by whom and when. It can be used as a process or product-centered format for example asking how each process step can fail or how each part or connection can fail and then quantifying those. Then is used to detect potential improvements.

In the previous posts weve looked at the tools most commonly used during each phase of a six sigma DMAIC project. In other words lets use the data obtained in the Measure Phase to identify the root causes that we want to fix. The Improve phase is the fourth phase of the DMAIC process.

Once the analyse phase deliverables are complete the next step is the improve phase. Additionally design the action plan. Students who viewed this also studied.

Its a five-phase methodDefine Measure Analyze Improve and Controlfor improving existing process problems with unknown causes. During the measure phase of DMAIC the project team should have a clear. The MEASURE phase involves more numerical studies and data analysis than the DEFINE phase.

Common six sigma tools DMAIC used at this stage are root cause analysis failure mode and effects analysis FMEA 5Why fishbone diagram and hypothesis testing. Design DFMEA and Process PFMEA. It consists of five basic phases.

Multi-vari chart to detect different types of variation within a process. All ideas for possible solutions are to be regarded in order to encourage participation by team members. Every project is different of course but tools typically used during the dmaic analysis phase include linear regression design of experiments and Pareto analysis.

Define With respect to the several types of individuals in six sigma projects ___ work across the organization to develop and coach teams conduct training and lead change but are typically not members of six. To find out more about six sigma tools used in the DMAIC process other than the analyse phase. The MSA will quantify the amount of variation found in the data that is induced from the measurement system.

Failure mode and effects analysis FMEA for identifying possible product service and process failures. A Define b Measure c Analyze d Control Question 15 5 5 points Lean is based on the manufacturing system that was developed by. This process is also known as DMAIC pronounced duh-may-ik its acronym.

DMAIC is based on the Scientific Method and its pronounced duh-may-ik. Improve process performance by addressing and eliminating the root causes. The main activity in the Improve phase is to determine the solutions for the problems identified in the first three phases of DMAIC.

The DMAIC process is a data-driven improvement cycle for optimizing and stabilizing business processes and designs. Design FMEAs focus on how each element in the design could fail starting with higher level systems. This phase pushes you to think of out-of-the-box solutions that are innovative and consistent.

Dmaic With Accompanying Tools Process Map Change Management Lean Six Sigma

A Schematic Overview Of The Six Sigma Dmaic Process And Associated Tools Download Scientific Diagram

7 Quality Tools For Problem Solving Explained Visit For Complete Presentation In 2022 Process Improvement Correlation Graph Data Collection Sheets

Failure Mode And Effects Analysis Fmea Analysis Engineering Tools Job Board

Digital Six Sigma Dmaic Improvement Process Objective Main Activities Key Deliverables Team Charter Project Problem Solving Worksheet Lean Six Sigma Lean Sigma

How Does Lean Six Sigma Work Goleansixsigma Com Lean Six Sigma Sigma Lean

Lean Six Sigma Tools Understand The Purpose Of These Tools Lean Six Sigma Agile Project Management Templates Agile Project Management

Home Lean Process Operations Management Change Management Lean Six Sigma

What Is Dmaic Business Performance Improvement Bpi

Lean Six Sigma Lean Sigma How To Plan

Fmea Failure Mode Effect Analysis Lee Ky Six Sigma Others

Lean Six Sigma Sipoc Infographic Goleansixsigma Com Lean Six Sigma Process Improvement Lean Sigma

Lean Six Sigma Black Belt Lean Six Sigma Change Management Business Management Degree

Six Sigma Dmaic Methodology Lean Six Sigma Six Sigma Tools Sigma

The Six Sigma Dmaic Process And Key Outputs 17 Download Scientific Diagram

Lean Six Sigma Dmaic Poster 3 Page Pdf Document Flevy

Six Sigma Project Report Template For Microsoft Powerpoint Report Template Problem Statement Templates

Comments

Post a Comment